TECHNOLOGY

Right... and all right!

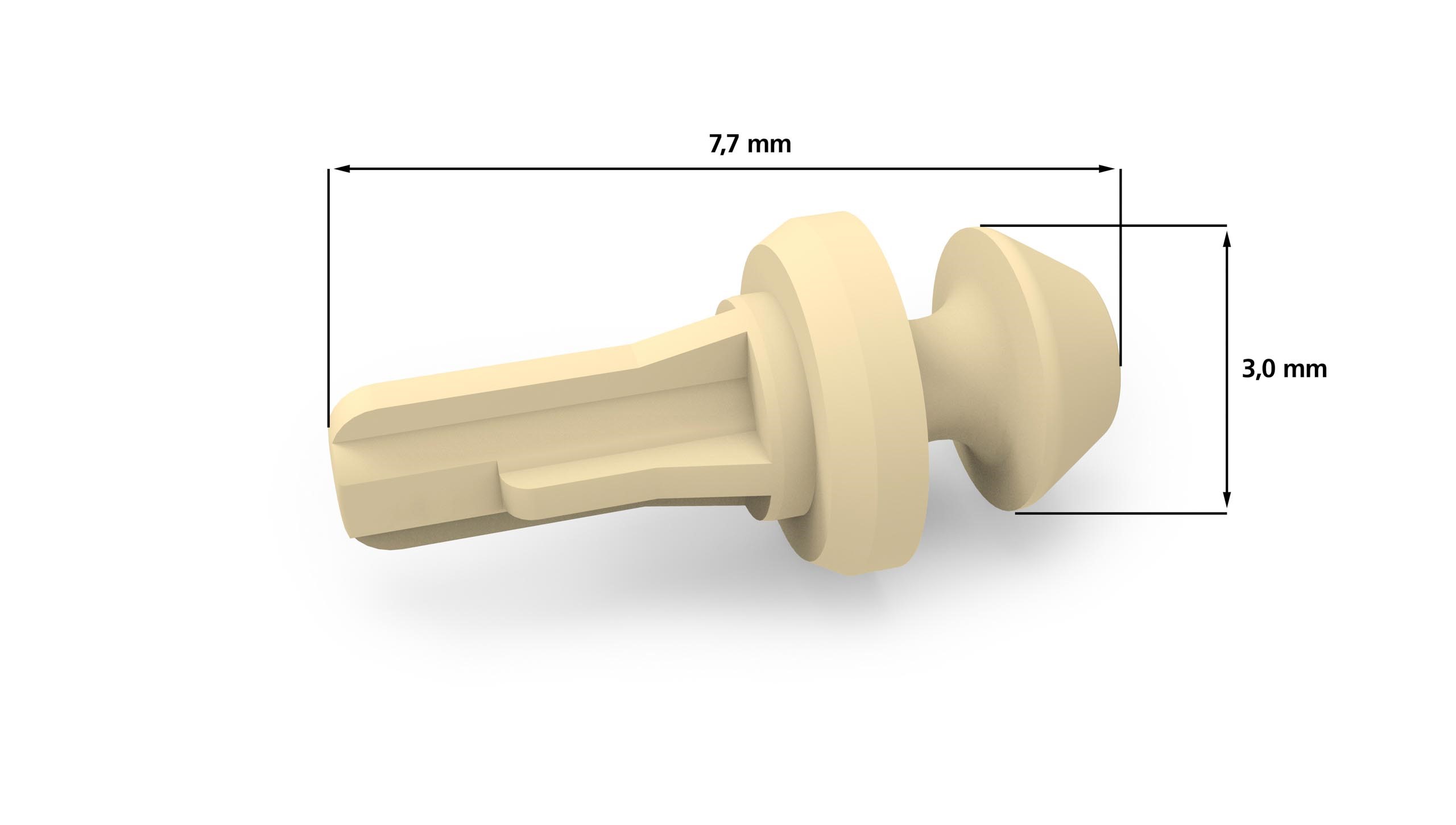

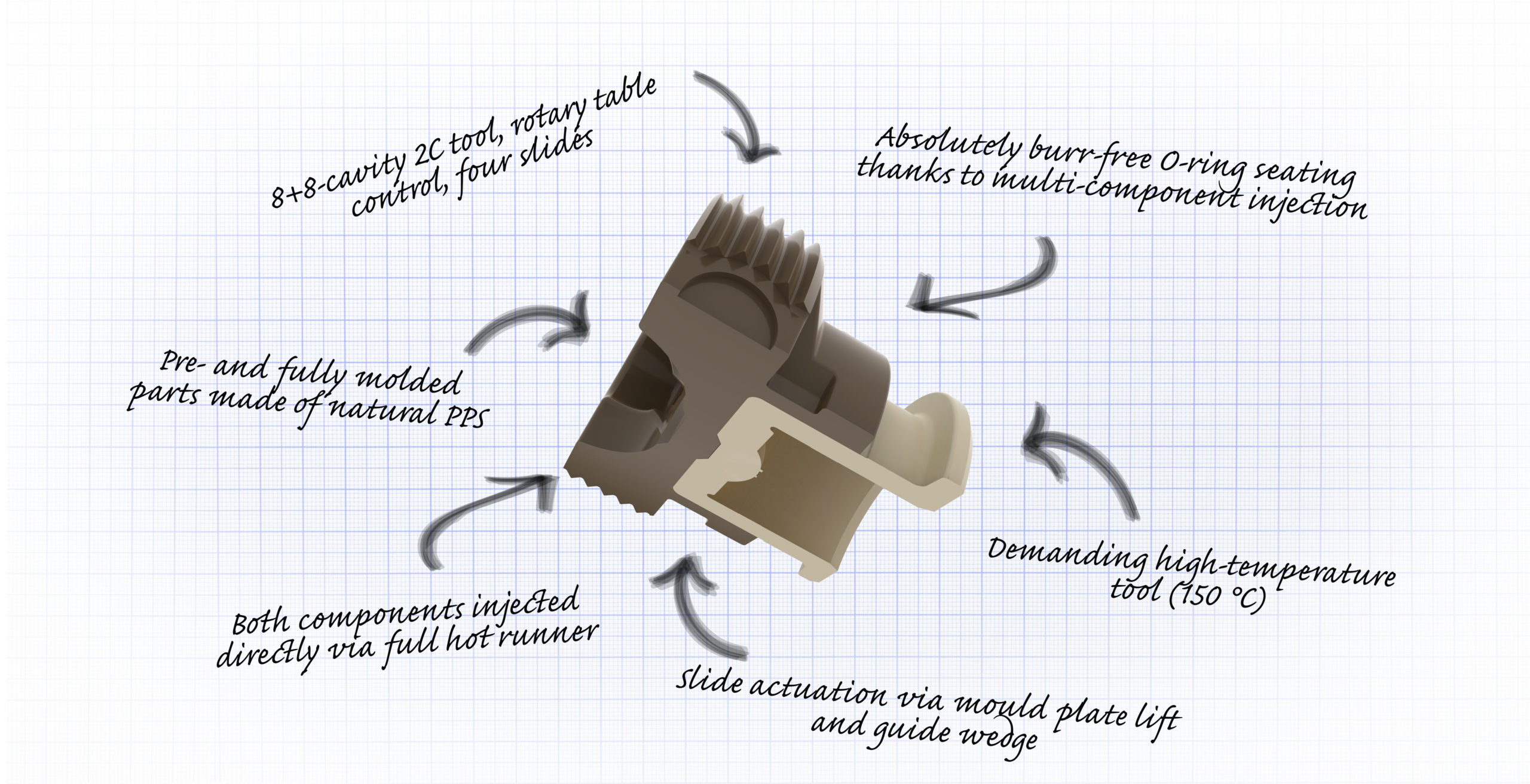

Multi-component injection moulding: Automotive component adjusting screw.

When we handle your injection-moulding tasks, we push the limits of what’s possible! Whether it’s micro-injection moulding or precision injection moulding, technical thin-walled and multi-components or hybrid components, we offer the best solution for your needs.

Right… and all right!

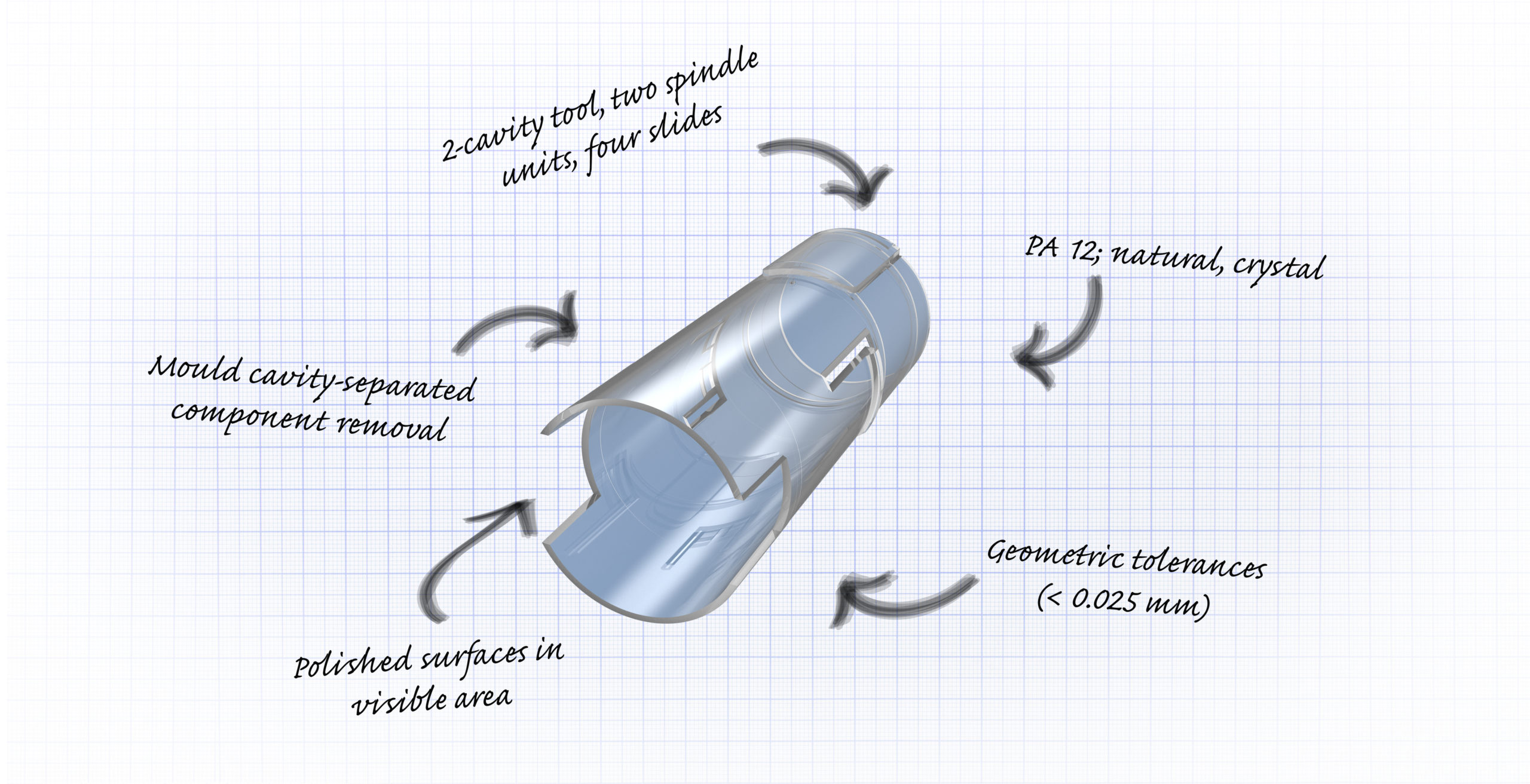

Precision injection moulding: Housing for fibre optic connection for use in information technology.

Micro- and precision-injection moulding

Big things in small packages.

Micro- and precision-injection moulding:

- Production of high-precision plastic parts with microstructures and/or micro-dimensions with a part weight below 0.001 g

- Removal devices with high acceleration values and repetition precision of ≤ 0.03 mm

- Uniform filling of high-cavitation micro-injection-moulding tools

- Process regulation procedures with elaborate sensors and regulation technology

- External measurement data system for the recording, monitoring and evaluation of important process parameters

- Plane-parallelism/position precision of ejector and nozzle side < 5 μm

- Burr-free bores up to a core diameter of 0.16 mm

- Precise balancing of the cold runners, even with high-cavitation tools

- Use of micro-hot runner systems with valve gate

- Precise close-contour insert temperature control

- Consistent wall thicknesses

- Material exemptions, including for micro-parts

- Precise implementation of ventilation tracks within 2 μm

- Smallest gate diameters of 0.1 mm reproducible across mould cavities

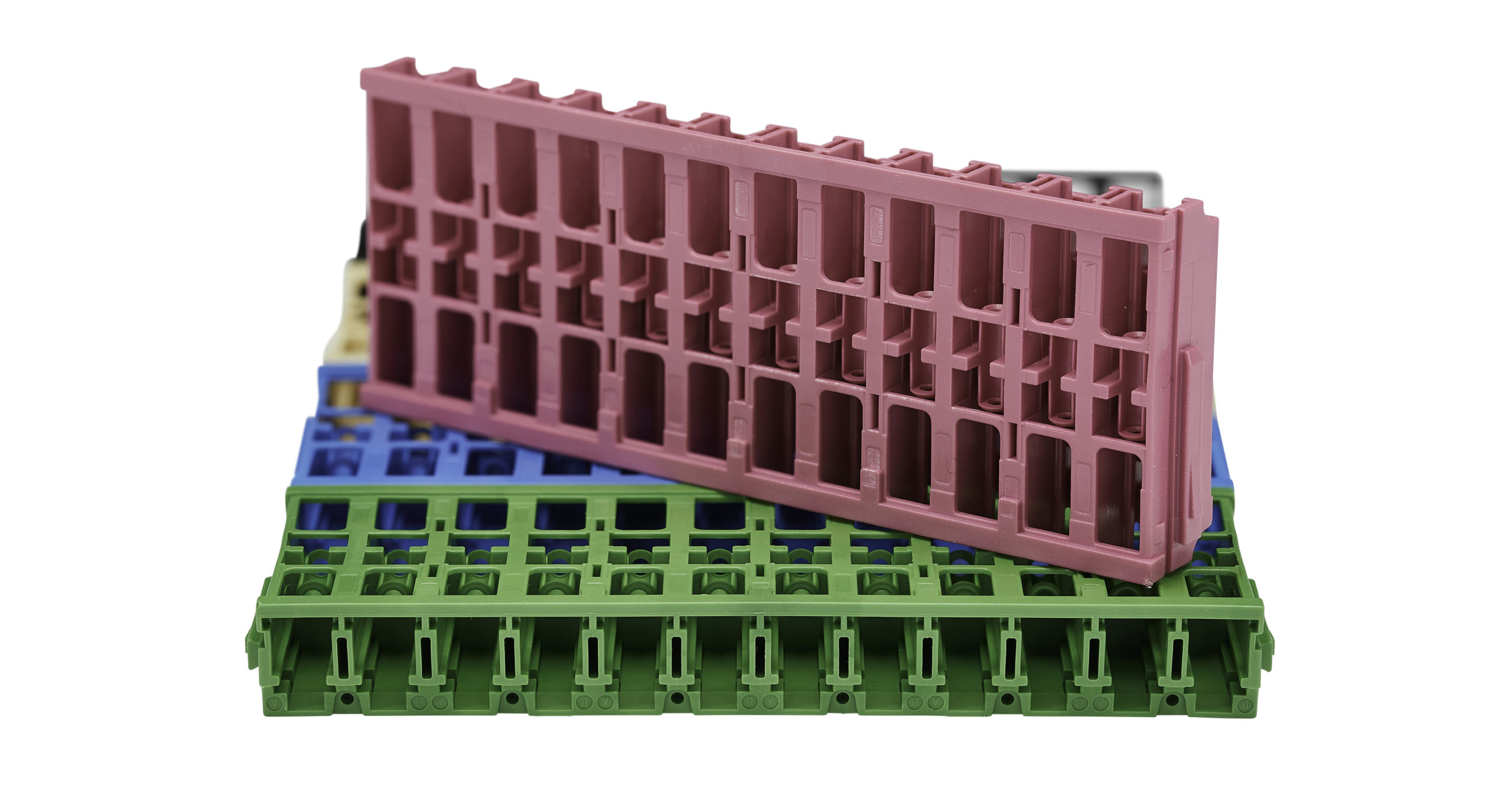

Micro-injection moulding: Rocker switch for electrical engineering.

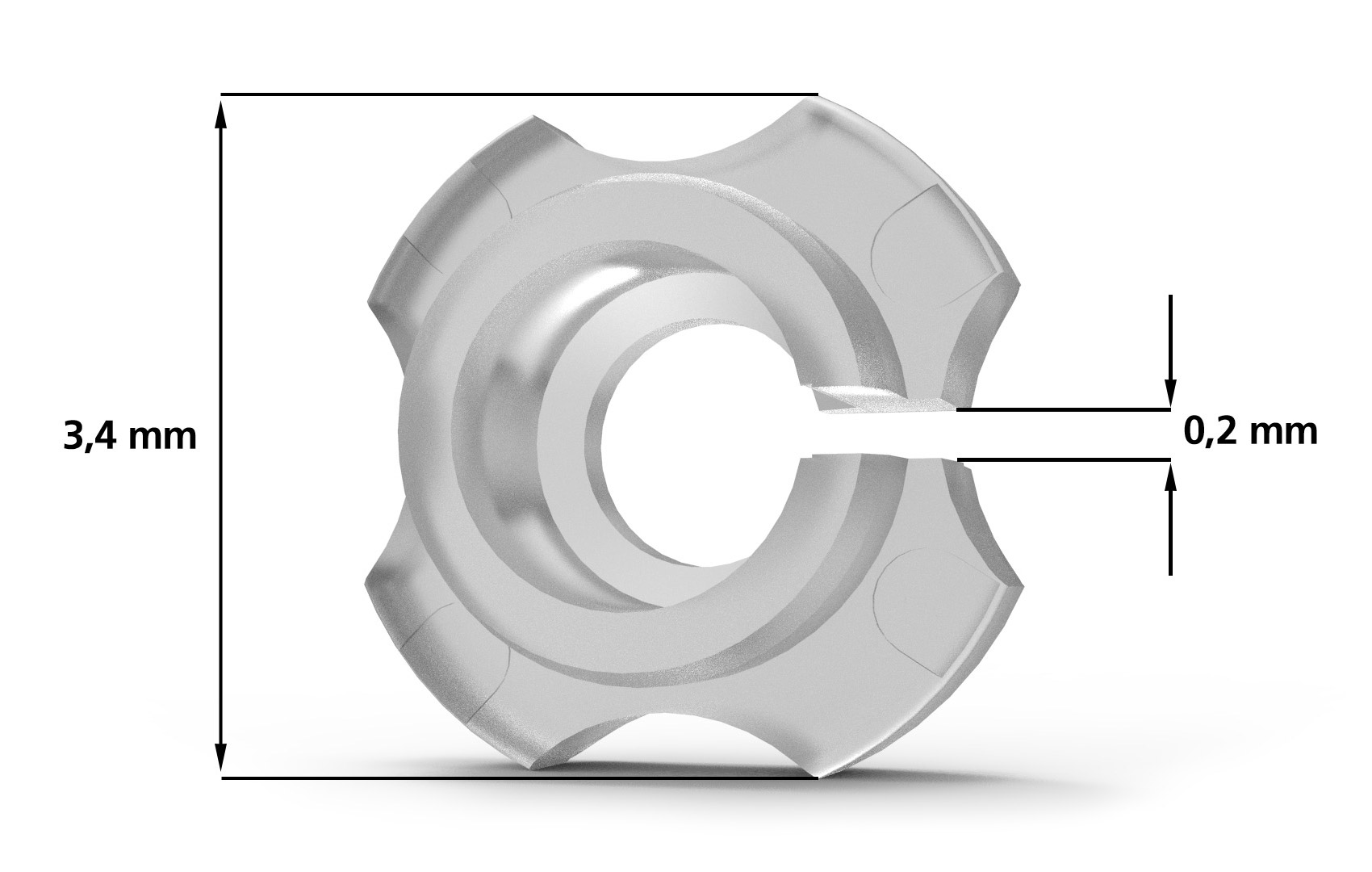

Technical thin-wall injection moulding

Always dimensionally accurate – and that includes thin-walled parts.

Technical thin-wall injection moulding includes:

- The smallest of wall thicknesses of 0.2 mm, depending on the material and component geometry

- For technical materials, a flow path wall thickness ratio of 150:1, depending on the material and absolute wall thickness

- Use of injection-moulding machines with high injection dynamics and injection power

- Maximum reproducibility

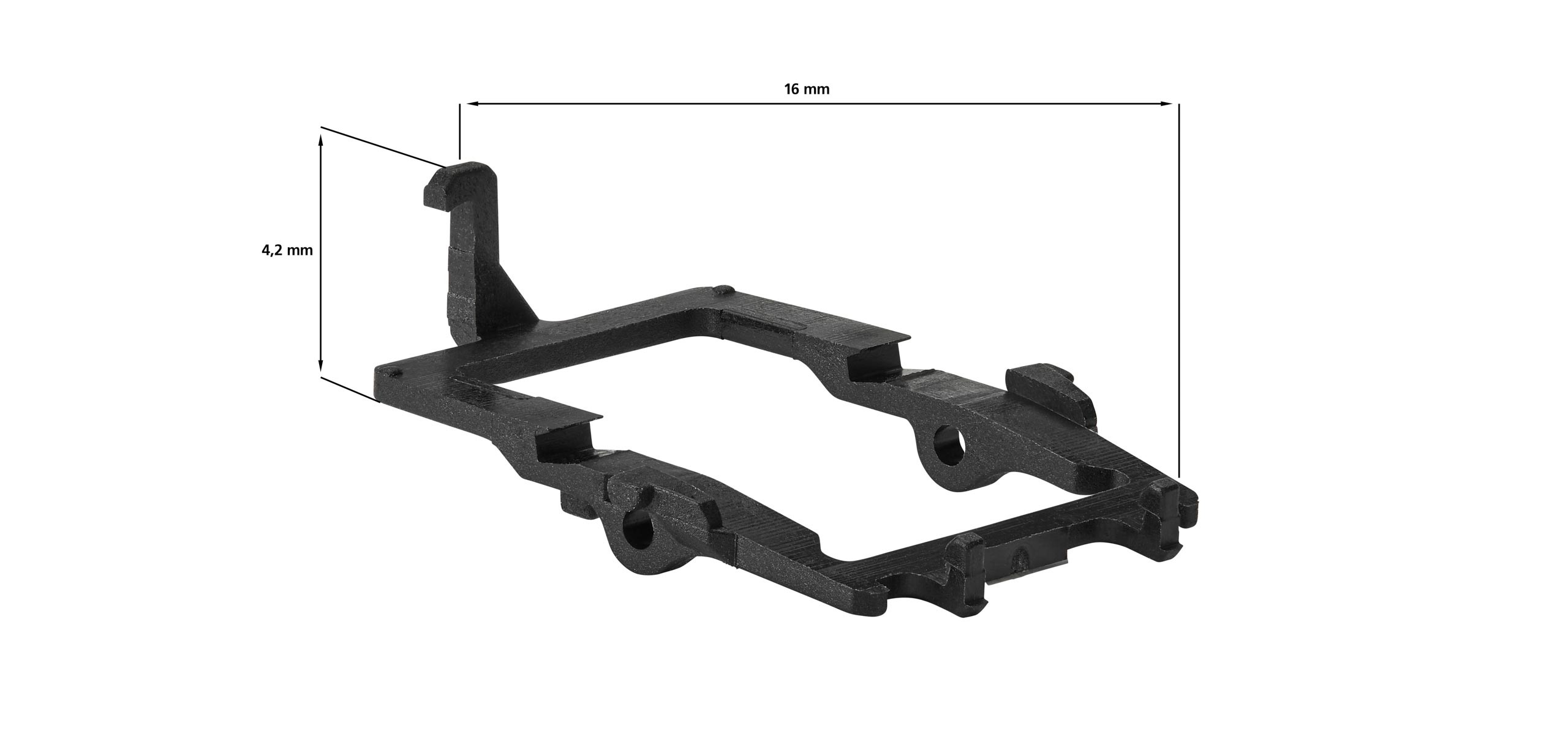

Precision injection moulding: Module cover of a clockwork.

Multi-component injection moulding

Diverse processes.

For multi-component injection moulding, we’re able to offer the following processes:

- Overmoulding

- Index plates

- Rotary table

- Core back

- If required, thermal separation of the plastic components in the tool

- Use of electrically driven core pulls and/or unscrewing devices possible

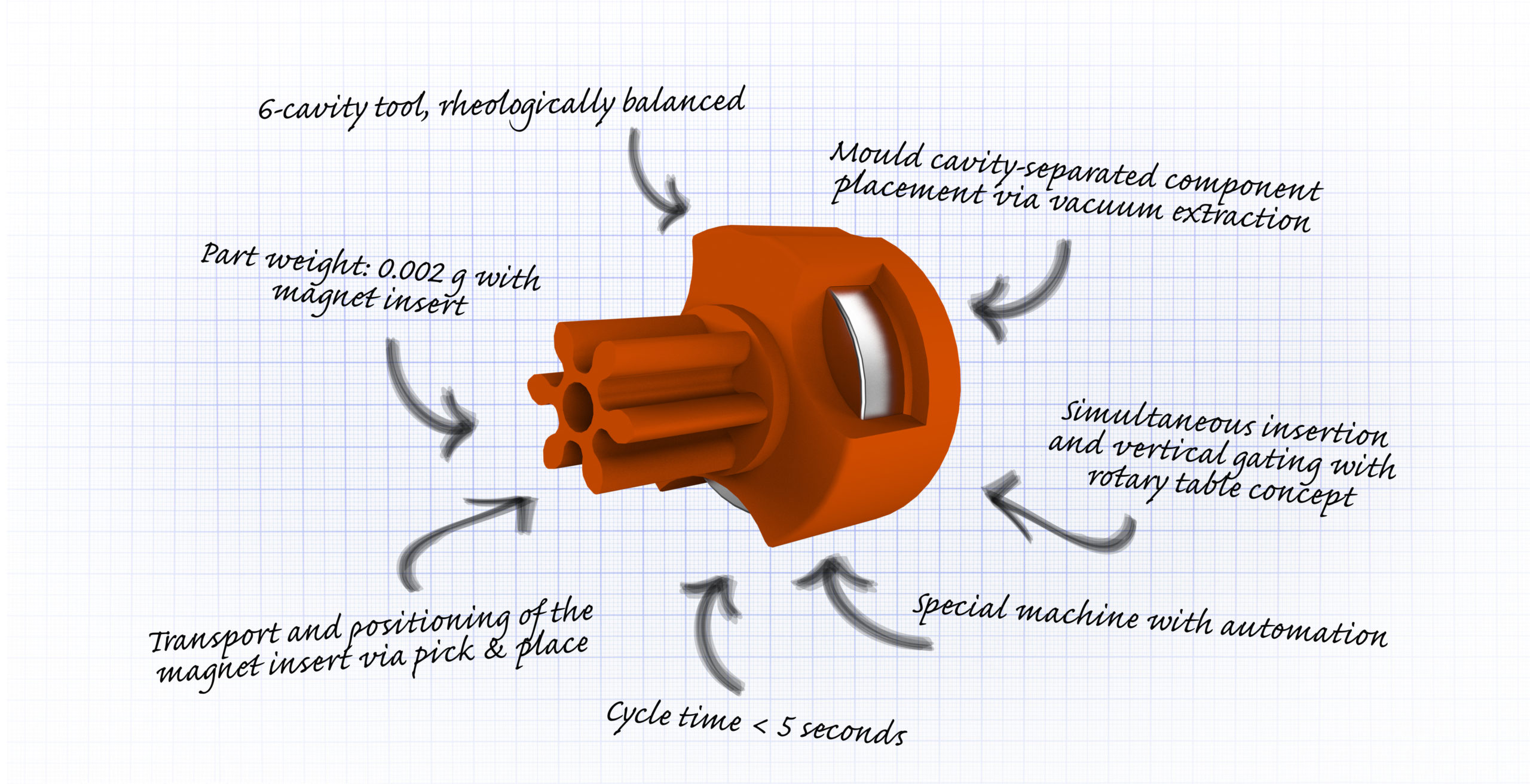

Micro-injection moulding: Spring guide – an important component of drinking water treatment.

Hybrid parts

Joining materials!

For your hybrid parts, we offer:

- Implementation of interlocking and/or adhesive connections between plastic and inserts

- Universal injection-moulding machines for hybrid production, e.g. overmoulding metal inserts

- High-precision positioning of inserts with the smallest of dimensional tolerances using a robot, repetition precision: 3/100 mm

- Preheating of inserts and/or temperature control of the hybrid components for the smallest possible process fluctuations